Total Elimination of Listeria SP from High Care Environment Leading RTE Poultry Processing Plant

Hot-dog production is challenging due to conditions that allow the proliferation of dangerous bacteria such as Listeria or Salmonella, which in turn lead to the obvious danger of product cross contamination.

An environment free of dangerous bacteria is essential for Food safety.

A leading Israeli RTE meat producer with high-quality products and an uncompromising food safety policy suffered from continuous positive Listeria presence on floors and drainage system in the High Care departments, although strict sanitation was performed up to 3 times per day up to 11 hours.

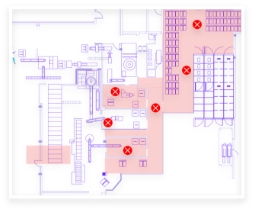

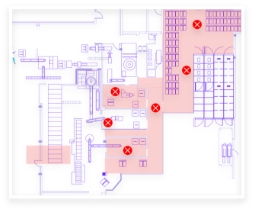

Before

Coating with Bio-Fence technology

Floor sampled twice a day showing

91% listeria presence Enterobacteria >106 T.C >106

-

MAY 2021

MAY 2021

-

After

Coating with Bio-Fence technology

Immediate improvement

0% Listeria presence Enterobacteria <101 T.C <101

Results and operational savings

-

1

Floor sampling – moving from 2 a day to 2 a month (95% reduction)

-

2

Floor sampling – reduction from an average of 45-91% positive listeria readings to 0.5%

-

3

5 log reduction in EB and TC – Improve total hygiene

-

4

Sanitation – 40% Reduction in time, labor and chemicals

-

5

75% reduction in water, energy and effluent

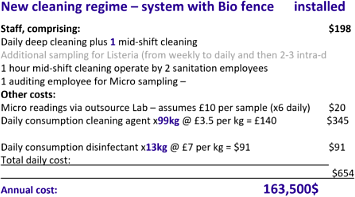

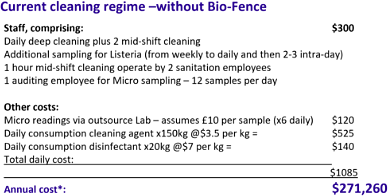

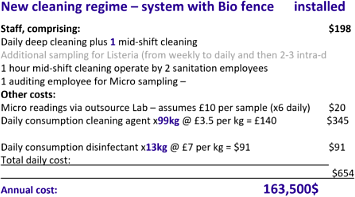

Customer ROI 750 Sqm High Care

Coating cost: $75,000 (Labor +Material )

Bio-fence technology added cost: 20$ per sqm=$ 15,000

Total coating cost = $90,000 | 5 years lifetime

Annual operational savings: $107,760 (-40%)

Annual operational savings: $107,760 (-40%)

Are you ready to create a pathogen free production environment?

Contact us!

Tiv Tirat Zvi is a leading Israeli RTE meat producer supplying premium high-quality products alongside an uncompromising food safety policy.

The site decided to adopt Bio-fence's antimicrobial coating technology to enhance hygienic conditions in the production departments.

After 14 months of usage, it is evident that Bio-fence's antimicrobial coating technology can help ensure ultra-hygienic conditions in a cost-effective manner. The site has decided to implement Bio-fence's technology in additional departments.

According to Haysa Shai, the site's QA manager, "using Bio-fence's coating technology introduces better environmental hygiene and provides peace of mind regarding the presence of pathogens on floors and drainage systems in high-care departments."

Are you ready to create a pathogen free production environment?

Contact us!

Milouoff is a leading manufacturer of frozen RTE poultry products that primarily serves the institutional market in Israel. Food safety is a major concern and the site is continuously working to produce safe, high-quality products.

The company recently rebuilt the RTE packaging department, a high-care zone, and adopted Bio-fence's coating technology to eliminate pathogens and achieve better environmental hygiene.

Following implementation, a routine micro sampling resulted in a zero reading of Listeria and Salmonella, and an extremely low presence of both Total Count and Enterobacteria on the freshly coated surfaces. Since intermediate sanitation steps become unnecessary, Bio-fence's technology also provides substantial savings in time, labor, micro-sampling, and chemical use.

According to Yohai Ben Zikri, the company's chief technologist:

“This is the first time, in all my 40 years of experience, that I can see a real antimicrobial coating technology that works in challenging real-life conditions and brings real value. With Bio-fence technology, we are achieving a high standard of environmental hygiene with no need for additional resources other than the daily sanitation routine. We will extend the use of Bio-fence coating to other parts of the site.”

Are you ready to create a pathogen free production environment?

Contact us!

Annual operational savings: $107,760 (-40%)

Annual operational savings: $107,760 (-40%)